Acme Sic Sintering Furnace, Aln Sintering Furnace, Zro Sintering Furnace, Vacuum Sintering Furnace

Description

Basic Info.

| Model NO. | HVSF-050511 |

| Heating Element and Muffle | Isostatic Press Graphite/High Purity |

| Furnace Vessel | All Carbon Steel/Inner Layer Stainless Steel/All S |

| Thermocouple | C Type/S Type/R Type/B Type |

| Pyro-Meter | Dual-Color/Single Color |

| Process Gas System | Volume/Mass Flow-Meter |

| Ultimate Vacuum (PA) | 1-100 |

| Furnace Door | Screw/Hydraulic/Manual Elevation |

| Pressure Increase Rate (PA/H) | 0.67 |

| Max. Temperature (°c) | 1500/2400 |

| Temperature Uniformity (°c) | ±5/±10 |

| Working Zone Size | 500×500×1100 |

| Transport Package | Wooden Box |

| Specification | 500× 500× 1100 |

| Trademark | ACME |

| Origin | China |

| HS Code | 8514199000 |

| Production Capacity | 50 |

Product Description

Product Description

The furnace is used for reaction sintering, low pressure sintering, re-crystal sintering of ceramic product, and it can also used for production of ceramic powder. It has both horizontal and vertical structures.

Application

Ceramic products such as SiC, silicon nitride and aluminum nitride.

Product specification

| ModelSpec | Working Zone Size (W×H×L) (mm) | Max. Temperature (°C) | Temperature Uniformity (°C) | Ultimate Vacuum (Pa) | Pressure Increase Rate (Pa/h) |

| HVSF-050511 | 500×500×1100 | 1500/2400 | ±5/±10 | 1-100 | 0.67 |

| HVSF-100612 | 1000×600×1200 | 1500/2400 | ±5/±10 | 1-100 | 0.67 |

| HVSF-100813 | 1000×800×1300 | 1500/2400 | ±5/±10 | 1-100 | 0.67 |

| HVSF-100825 | 1000×800×2500 | 1500/2400 | ±5/±10 | 1-100 | 0.67 |

| HVSF-100840 | 1000×800×4000 | 1500/2400 | ±5/±10 | 1-100 | 0.67 |

| VVSF-0612 | φ600×1200 | 1500/2400 | ±5/±10 | 1-100 | 0.67 |

| VVSF-0917 | φ900×1700 | 1500/2400 | ±5/±10 | 1-100 | 0.67 |

| VVSF-1015 | φ1000×1500 | 1500/2400 | ±5/±10 | 1-100 | 0.67 |

| VVSF-1120 | φ1100×2000 | 1500/2400 | ±5/±10 | 1-100 | 0.67 |

| The above parameters can be adjusted to the process requirements, they are not as acceptance standard, the detail spec. will be stated in the technical proposal and agreements. | |||||

Technical Features

1.Using unique ACME super high temperature and high current power supply technology, it can long term stable use at high temperature;

2.Using special designed high temperature pyro-meter measuring technology with precision temperature control and small deviation;

3.Installed with special sealing muffle to minimize the silicon vapor and exhaust gas contamination to the heating element and insulation;

4.Installed high efficiency exhaust gas treatment device , which is environment-friendly and convenient to clean;

5.It has debinding system, to complete debinding and sintering process in one furnace at one time.

Optional Configuration

1.Furnace door: screw/hydraulic/manual elevation; manual tight/auto lock-ring tight

2.Furnace vessel: all carbon steel/inner layer stainless steel/all stainless steel

3.Furnace hot zone: soft carbon felt/soft graphite felt/rigid composite board/CFC

4.Heating element and muffle: isostatic press graphite/high purity, strength and density graphite/fine size graphite

5.Process gas system: volume/mass flow-meter; manual/auto valve;

6.Thermocouple: C type/S type/R type/B type

7.Pyro-meter:Dual-color/Single color; CHINO/Raytek

Project process

discussion on technical questions--prepare technical proposal and commercial quotation--confirm technical proposal--sign contract--Advance payment(T/T)--layout drawing discussion and confirmation--production--installation and commissioning--quality inspection--Pre-acceptance--second payment(T/T)--disassembling and packaging--dispatch and shippment--installation , commissioning and training at Buy's plant--final acceptance-- final payment(T/T)--after-sales service

WHAT CAN WE DO FOR YOU?

Basic Functions: A R&D Center For New Equipment A;Pilotscale Experiment Platform For Customer A; Teaching Practice And Training Base.ACME Provides Custom Furnace Design Service, Though We Have Standard Specifications. Our Custom Furnace Systems Can Reach Extremely High Heating Temperature, And Create High-Quality Finished Products. Our Highly Experienced Engineers Can Design The Furnace In The Way You Want - As Big As You Need.The Furnace Can Operate At Your Desired Temperature, And Produce The Large Quantity And High Quality Products. Whether You Are More Concerned With Costs Or Capabilities, Our Custimized Furnace Will Meet Those Needs. Our Furnaces Are Designed To Do Our Best To Meet Your Application, Budget And Schedule Requirements.All The Products Sold Out Can Enjoy One Year Warranty. All ACME Customers Have Access To Aftermarket Replacement Parts, Spare Parts, Repair And Maintenance Services To Keep Their Furnaces Up And Running. ACME Owns Maintenance Records And Part Lists For Every Furnace We Have Ever Built, So Just A Phone Call Or An Email, You Will Get The Help From Us.

FAQ

Q1: Are you a factory?A1: Yes, we are a large factory that integrates research and development design, manufacturing and sales.Q2: Do you have technical support for the treatment technology and equipment ?A2: Yes. we could provide the customer with mature technical support.

Q3: What is the advantage about your company?A3: We have large factory, have special technical teams, who know the technology, process and equipment, have test center with many equipments which can treat customers' products before contract, best and fsat after-sales service, have much experience, have high credit and good economic basement.

Q4: Why should I choose your products?A4: Our products are high quality and reasonable priceQ5: Any other good service your company can provide?A5: Yes,we can provide good after-sale and fast delivery

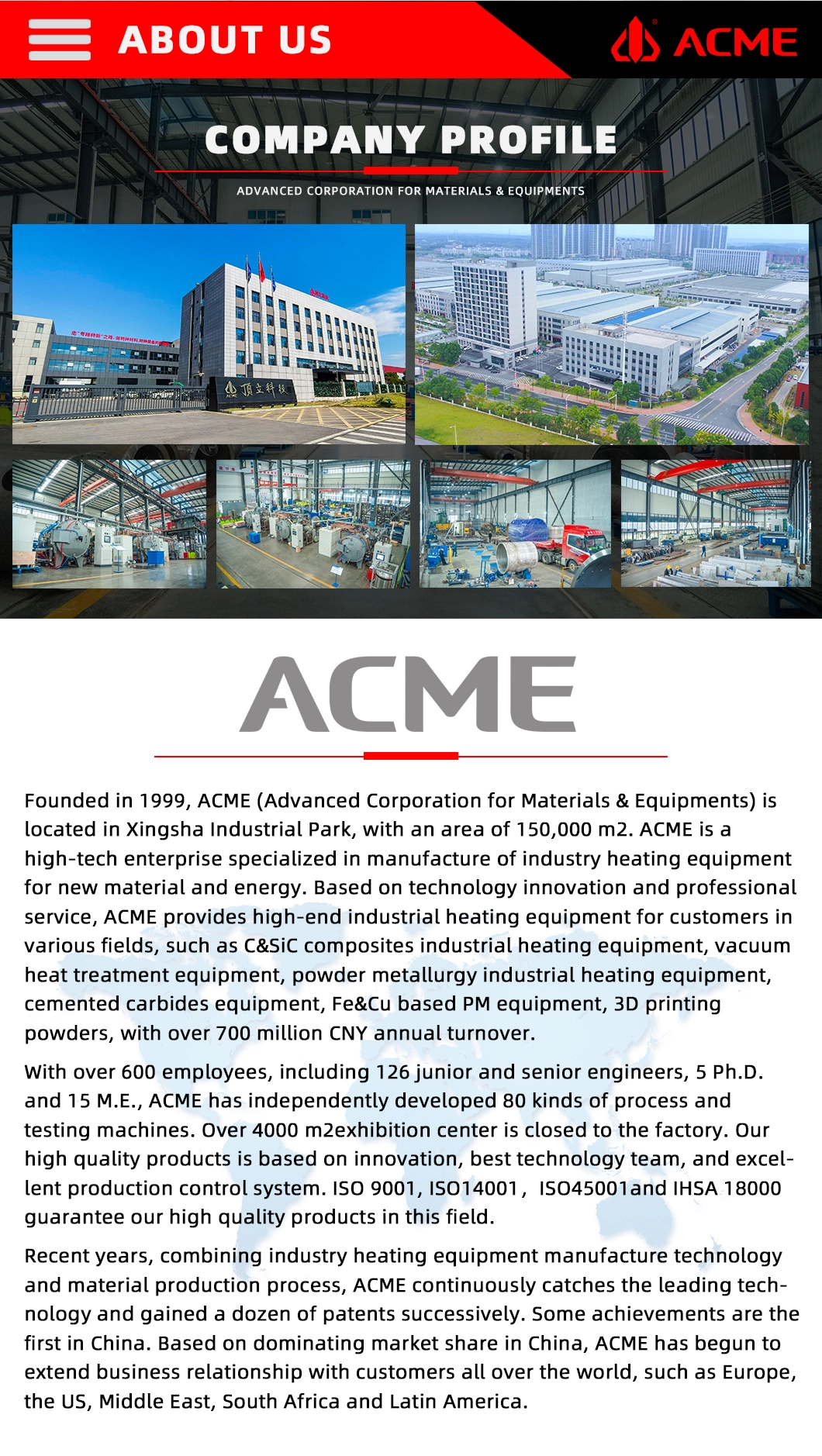

Company Profile

Our Contact